The importance of choosing the right support

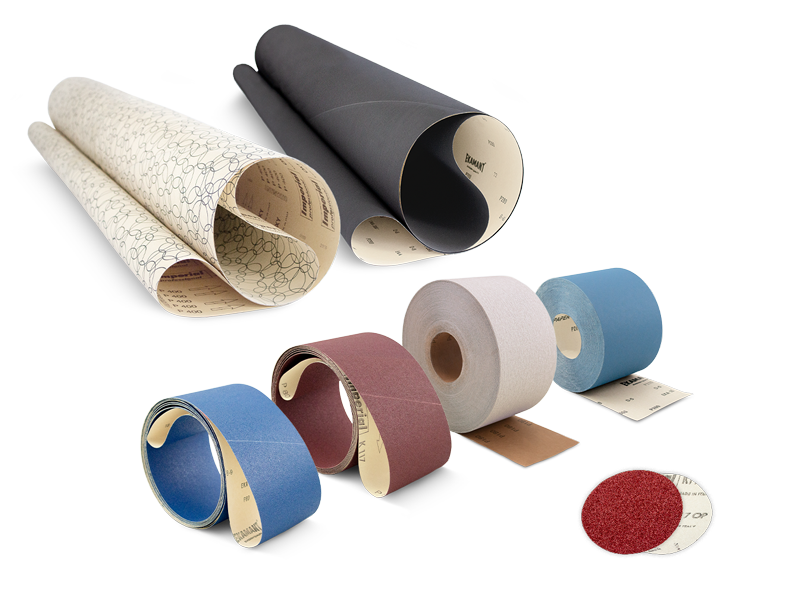

In the field of flexible abrasives we find different types of supports: Paper, cloth, combination, sponge, film, mesh, non-woven fibre and vulcanised fibre.

The support is a determining component in the composition of an abrasive.

Depending on the sanding application and the media available, the abrasive backing must meet a series of requirements during sanding work: resistance, flexibility, lightness, adaptability, etc.

PAPER Supports

Paper support is economical and is used in sanding applications with low strength requirements. Papers are classified according to their weight per square meter from class A for very light papers to class G for very heavy papers:

Paper A

< 80g/m2

Paper B

85-109

Paper C

110-134

Paper D

135-160

Paper E

220-269

Paper F

270-350

Paper G

350-500

Paper H

>500g/m2

FABRIC or WOVEN FIBRE supports

Fabric supports are typically used in sanding applications with higher strength requirements. They are identified according to their degree of flexibility and can be rigid, semi-rigid or flexible.

The materials used for the fabric supports are: cotton, polyester or a combination of these. Flexible fabric supports are ideal for good adaptability and uniform finishes, while rigid substrates will provide greater aggressiveness and a poorer surface finish. Fabrics with polyester can be used for wet sanding.

JF fabric

Ultra-flexible

cotton

F fabric

Flexible

cotton

J fabric

Semi-flexible

X fabric

Rigid cotton

Y fabric

Rigid

polyester

XY fabric

Rigid cotton

and polyester

YY fabric

Extra-rigid

polyester

COMBINATION supports

Combination supports are mixed supports, reinforced by a layer of fabric and other paper layers. They are designed for the manufacture of large abrasive belts that have to withstand heavy stresses. The paper prevents the fabric from stretching and the fabric prevents the paper from tearing.

SPONGE supports

Supports with a sponge base generate a cushioning effect on the abrasive, facilitating precise and uniform finishes, without over-sanding. It is the ideal support for sanding curved areas for machine and manual applications. It adapts to irregular surfaces providing constant sanding and a homogeneous finish.

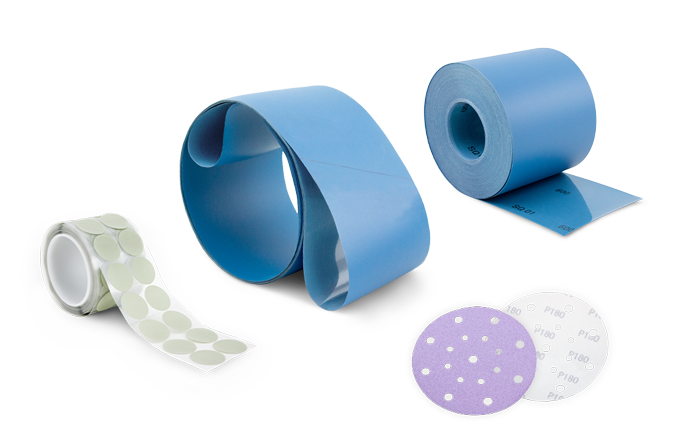

FILM supports

Polyester film-based supports have a constant thickness and allow very uniform finishes to be achieved. The polyester film also adds flexibility and durability to sanding operations. In addition, the film support is tear-resistant and waterproof, being unaffected by changes in temperature and humidity. It can be used for dry and wet sanding jobs.

MESH supports

Polyamide mesh supports facilitate maximum dust extraction and a clean, operator-safe and environmentally friendly sanding experience.

NON-WOVEN FIBRE supports

Non-woven fibre supports, commonly known as scotch, consist of a skein-like web of non-woven yarns. They stand out for their great cushioning capacity during sanding operations, especially manual sanding operations. They are very flexible and adapt to contours, shapes and hard-to-reach areas.

This type of support achieves a uniform, fine and smooth finish thanks to the optimal distribution of pressure on the support, eliminating pressure points. They are waterproof, washable and reusable. The open structure of the support facilitates easy removal of residue from the sanded material.